Unlocking the Power of OEE Monitoring

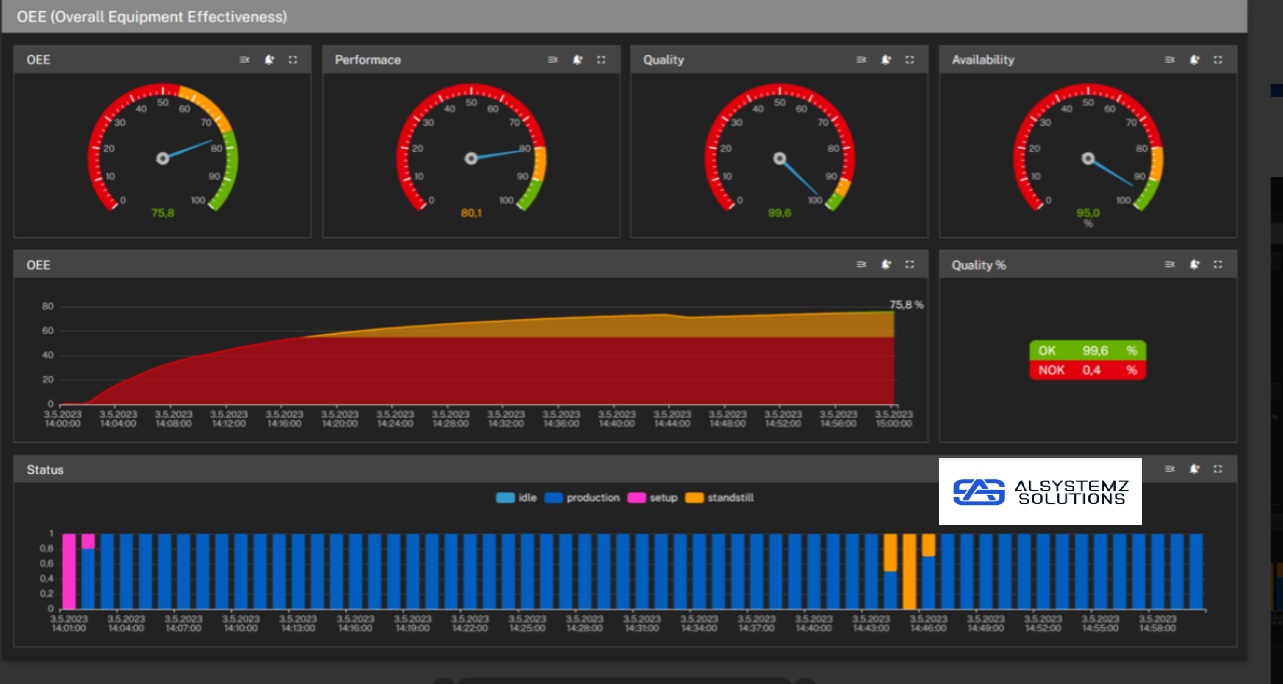

OEE provides a framework for understanding how effectively a manufacturing process is operating. It measures equipment effectiveness by breaking it down into three components:

- Availability: How often equipment is available and running when scheduled.

- Performance: How fast equipment runs compared to its maximum potential speed.

- Quality: The percentage of good parts produced versus total parts.

Our IoT-based systems provide companies with the ability to track these components in real-time helping them to make the most of their equipment. Here’s a closer look at how our solutions optimize each element of OEE.

1. Availability: Reducing Unplanned Downtime

One of the largest contributors to inefficiency in any industrial operation is unplanned downtime. Whether due to unexpected equipment breakdowns long maintenance periods or operator errors downtime significantly impacts a machine’s availability for production.

At AlSystemz Solutions our IoT systems continuously monitor equipment availability allowing businesses to act quickly when issues arise.

- Real-Time Downtime Alerts: Our IoT sensors provide real-time data on machine availability and send instant notifications when a machine experiences unplanned downtime. This allows operators to respond promptly and get production back on track.

- Predictive Maintenance: Using advanced data analytics we offer predictive maintenance solutions that anticipate when machines are likely to fail. This helps companies schedule maintenance before problems occur reducing unplanned downtime and improving machine availability.

- Proactive Maintenance Scheduling: Our solutions help businesses plan maintenance activities during non-productive periods ensuring that downtime is minimized.

By improving machine availability businesses can reduce costly interruptions and maintain consistent production levels.

2. Performance: Optimizing Equipment Output

Even when machines are available for production they may not always operate at peak efficiency. Performance is a measure of how fast equipment is running compared to its maximum design speed. A machine that runs slower than expected can create bottlenecks reduce output and impact overall productivity.

At AlSystemz Solutions we provide businesses with tools to monitor and optimize performance in real time.

- Real-Time Performance Tracking: Our IoT-based systems track equipment speed and output in real-time comparing actual performance to maximum capacity. This allows businesses to identify when a machine is underperforming and take corrective action to improve efficiency.

- Identifying Bottlenecks: Through our analytics platform businesses can identify specific machines or processes that are slowing down production. By addressing these bottlenecks companies can streamline operations and increase output.

- Optimizing Machine Speed: Our performance monitoring tools allow operators to make real-time adjustments to machine settings ensuring that equipment is always running at its optimal speed and producing the maximum amount of output.

By focusing on improving equipment performance companies can boost productivity and reduce the time required to complete production cycles.

3. Quality: Ensuring Consistent High-Quality Output

Maintaining high-quality production standards is essential for industries that deal with strict regulations or high customer expectations. Quality in OEE refers to the percentage of products that meet quality standards out of the total production output. Defective products or rework can cause waste and inefficiency which negatively impacts overall equipment effectiveness.

At AlSystemz Solutions we provide real-time monitoring solutions to help businesses maintain consistent product quality and reduce waste.

- Real-Time Quality Monitoring: Our IoT systems detect defects and quality issues as soon as they occur allowing operators to make quick adjustments and prevent further errors. This reduces waste and helps companies maintain high production standards.

- Reducing Waste and Rework: By identifying quality issues early our systems help businesses reduce the amount of rework and material waste improving overall operational efficiency.

- Ensuring Compliance: In regulated industries like pharmaceuticals product quality is critical for meeting compliance requirements. Our solutions help businesses maintain high-quality standards and adhere to industry regulations reducing the risk of non-compliance and costly recalls.

By improving product quality companies can reduce waste increase customer satisfaction and ensure that their operations meet regulatory standards.

The Benefits of OEE Monitoring for Industrial Operations

Implementing OEE monitoring through AlSystemz Solutions offers several benefits that can transform the way businesses operate. Some of the key advantages include:

- Increased Productivity: By tracking and improving equipment availability performance and quality businesses can significantly boost their production levels without needing to invest in additional resources. This leads to higher output and greater efficiency.

- Cost Savings: Improving OEE helps companies reduce downtime eliminate inefficiencies and minimize waste leading to lower operational costs. This enables businesses to achieve better results with fewer resources.

- Data-Driven Decision Making: Our IoT systems provide businesses with real-time data that can be used to make informed decisions about equipment and processes. This helps operators optimize workflows plan maintenance activities and implement improvements that drive long-term success.

- Compliance and Quality Assurance: For industries with strict regulatory requirements maintaining high-quality production is essential. Our solutions ensure that businesses can meet these standards while improving efficiency and reducing costs.

Why Choose AlSystemz Solutions for OEE Monitoring?

At AlSystemz Solutions we are committed to helping businesses unlock the full potential of their equipment through OEE monitoring and improvement. Our innovative IoT-based solutions provide businesses with real-time insights and analytics that enable them to optimize equipment performance reduce downtime and improve product quality.

Whether you are managing a complex production line or overseeing a pharmaceutical manufacturing facility our systems make it easy to monitor and improve OEE. With AlSystemz Solutions you can ensure that your equipment is always operating at its peak leading to increased productivity lower costs and a competitive edge in your industry.

Transform Your Manufacturing Operations with AlSystemz Solutions

In today’s competitive industrial environment maximizing equipment efficiency is key to long-term success. OEE monitoring through AlSystemz Solutions provides the tools and insights you need to optimize availability performance and quality—ensuring that your equipment is always operating at its best. By leveraging our IoT Technicalnology and expertise you can achieve greater operational efficiency reduce costs and stay ahead of the competition.

Unlock the power of OEE with AlSystemz Solutions where innovation meets operational excellence.

Leave a Reply