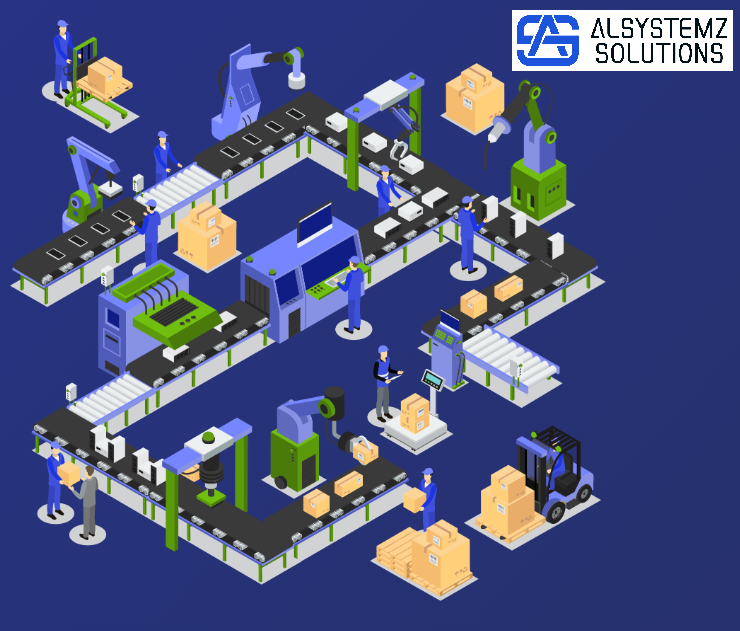

IoT-Based Production Management: Smart Manufacturing Solutions by AlSystemz Solutions

In today’s rapidly advancing manufacturing landscape businesses face increasing pressure to enhance efficiency reduce downtime and stay competitive. Traditional production methods often fall short in meeting these challenges with manual processes leading to errors inefficiencies and delays. To thrive in this environment manufacturers need advanced solutions that enable real-time monitoring predictive maintenance and seamless automation.

AlSystemz Solutions offers an innovative IoT-based production management system designed to streamline manufacturing operations. By leveraging IoT (Internet of Things) technology our solutions provide manufacturers with real-time visibility enhanced productivity and data-driven decision-making capabilities that elevate production processes to the next level.

In this blog we will explore how IoT is transforming production management and why AlSystemz Solutions should be your trusted partner for implementing IoT-driven solutions.

What is IoT-Based Production Management?

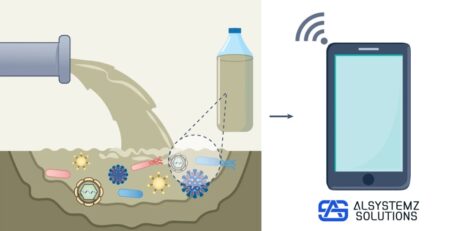

IoT-based production management involves the use of connected devices sensors and real-time data to monitor control and optimize production processes. These smart devices communicate with each other collect critical data from equipment tools and the factory floor and transmit this data for analysis. The result is complete visibility into every aspect of production—from machine health to process efficiency.

At AlSystemz Solutions we provide customized IoT-based production management systems tailored to the unique needs of each business. Our solutions enable manufacturers to automate repetitive tasks minimize production delays and maintain high product quality all while reducing operational costs.

Key Features of IoT-Based Production Management by AlSystemz Solutions

- Real-Time Monitoring: Our IoT sensors allow manufacturers to track equipment performance monitor workflows and gather production data in real time. This provides immediate insights and enables proactive adjustments to ensure optimal efficiency.

- Predictive Maintenance: By analyzing data from IoT-enabled sensors manufacturers can predict when machinery is likely to need maintenance. This proactive approach prevents costly equipment failures minimizes downtime and extends the lifespan of machinery.

- Automated Data Collection: IoT technology automates the collection of data from production processes eliminating the need for manual tracking. This leads to improved data accuracy faster decision-making and better resource management.

- Production Line Optimization: With IoT-based solutions manufacturers can optimize their production lines by identifying bottlenecks and streamlining workflows. This improves throughput reduces lead times and enhances overall efficiency.

- Energy Management: IoT sensors monitor energy usage across the production floor allowing businesses to identify inefficiencies and reduce energy consumption. This contributes to lower operational costs and supports sustainability goals.

- Quality Control: Our IoT solutions enhance quality control by detecting defects in real-time during the production process. This reduces waste ensures compliance with quality standards and improves customer satisfaction.

Why Choose AlSystemz Solutions for IoT-Based Production Management?

As a leading provider of IoT solutions AlSystemz Solutions offers a comprehensive approach to IoT-based production management. Here’s why businesses should choose us:

1. Tailored Solutions for Your Production Needs

At AlSystemz Solutions we understand that every manufacturing process is unique. We offer customized IoT-based solutions designed to fit your specific production requirements. Whether you run a small-scale operation or a large manufacturing facility our scalable systems can grow alongside your business.

2. Industry Expertise and Proven Technology

Our team consists of IoT experts with extensive experience in implementing advanced production management systems across various industries. We combine the latest IoT technologies with industry best practices to ensure that your production processes are optimized for maximum efficiency.

3. Seamless Integration with Existing Systems

We prioritize seamless integration with your existing production management tools enterprise resource planning (ERP) systems and software platforms. Our IoT solutions integrate smoothly with your current operations minimizing disruption and ensuring that the transition is effortless.

4. Real-Time Data for Informed Decision-Making

Our IoT-based production management systems provide real-time data and analytics empowering manufacturers with the insights they need to make informed data-driven decisions. This enhances productivity reduces errors and allows businesses to react quickly to changes in the production process.

5. Comprehensive Support and Maintenance

At AlSystemz Solutions we are committed to ensuring your success long after the installation of your IoT-based system. We provide 24/7 support ongoing maintenance and regular updates to ensure that your production management system continues to run smoothly and efficiently.

6. Cost-Effective Solutions for Sustainable Growth

Our IoT-based solutions are designed to deliver a strong return on investment. By reducing downtime optimizing resource utilization and automating workflows our systems help manufacturers lower their operational costs and improve profitability. Additionally our energy management features support sustainability efforts making your operations more eco-friendly.

How IoT-Based Production Management Transforms Manufacturing

Implementing IoT-based production management offers several key benefits that can revolutionize the way your business operates:

1. Improved Efficiency

By automating manual processes providing real-time insights and optimizing production workflows IoT solutions significantly improve manufacturing efficiency. This allows businesses to produce more in less time increasing throughput and reducing lead times.

2. Reduced Downtime and Maintenance Costs

Predictive maintenance powered by IoT technology helps manufacturers prevent equipment failures and avoid unplanned downtime. By scheduling maintenance before issues arise businesses can reduce repair costs and extend the life of their machinery.

3. Enhanced Product Quality

Real-time monitoring and quality control features ensure that defects are detected early improving product quality and reducing waste. This leads to higher customer satisfaction and fewer returns.

4. Lower Operational Costs

Automating repetitive tasks optimizing resource usage and reducing energy consumption all contribute to lower operational costs. Our IoT-based production management systems help businesses cut unnecessary expenses and improve profitability.

5. Increased Sustainability With our IoT-enabled energy management features businesses can optimize their energy usage reduce waste and minimize their environmental impact. This not only reduces costs but also supports corporate sustainability goals.

Leave a Reply